Electric valves

Leading products Global sales network

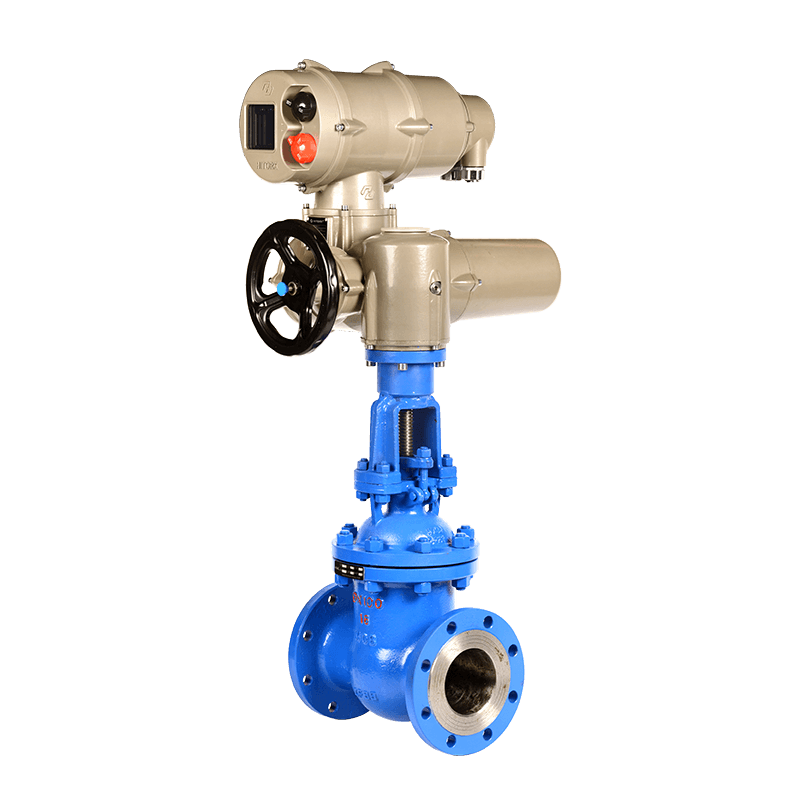

An electric gate valve involves the linear movement of the Gate Valve Electric Actuator controlled by electric voltage and signals to open or close the gate valve. These valves enable remote control, contributing to reduced labor costs and improved production efficiency.

Among the most commonly employed cutoff valves, the electric gate valve is primarily utilized for connecting or isolating the medium within pipelines rather than for adjusting the flow. It is well-suited for a broad range of pressures, temperatures, and calibers, particularly in medium to large diameter pipelines.

The electric gate valve finds application in various industries, including paper and pulp, power plants, shipyards, wastewater treatment, and more. It is suitable for handling water, oil, cement, paper pulp, and other mediums, making it a versatile solution for diverse industrial scenarios.

>Reasonable structure, reliable sealing, excellent performance, and beautiful appearance

>The sealing surface is welded with Co based alloy, which is wear-resistant, corrosion resistant, good scratch resistance, and long service life

>The valve rod is subject to tempering and surface nitriding treatment, with good scratch resistance and corrosion resistance

>The valve is equipped with an inverted sealing structure, ensuring reliable sealing

>Parts materials, flanges, and butt weld sizes can be reasonably selected according to user requirements to meet various engineering needs

>Equipped with HITORK pneumatic actuator, it can achieve stable and reliable operation of the valve

1 The fluid resistance is minimal. The internal medium channel of the gate valve body is straight, and the medium does not change its flow direction as it passes through the gate valve, This design makes the opening and closing process more effortless. When opening or closing, the gate moves perpendicular to the direction of medium flow. In comparison to a globe valve, the operation of the gate valve requires less effort.

2 The flow direction of the medium is typically unrestricted. The medium can flow in either direction from both sides of the gate valve, allowing for effective switching on or off. It is easy to install and well-suited for pipelines where the flow direction of the medium may change.

Gate valves are catagorized into rising stem gate valves and non-rising stem gate valves based on stem structure and movement mode.

In a rising stem gate valve, The stem drives the gate up and down simultaneously, with the drive thread located outside the valve body. This design allows for intuitive assessment of gate opening, closing and position based on the stem's movement direction and position .The drive thread is also convenient for lubrication and remains unaffected by fluid corrosion. However, it requires a larger installation space.

In a non-rising stem gate valve, the drive thread is located inside the valve body. During the opening and closing process, the valve stem only rotates, causing the gate to move up and down inside the valve body. Therefore, the valve's height dimension is smaller. Non-rising stem valve gates are usually equipped with an opening and closing position indicator above the valve cover, This feature makes them suitable for environments with limited space and high dust content, such as ships and pipe trenches.

Gate valves can also be divided into wedge type and parallel type according to the structure of the gate.

Wedge gates can be divided into rigid single gates, flexible single gates and double gates.

The wedge-type rigid single gate is simple in structure, small in size, and reliable in use. However, the processing and matching accuracy of the wedge angle is relatively high, and it is prone to clamping and scratching. It is suitable for gate Valves operating with various media and pressures at room or moderate temperature.

The wedge-type elastic single gate relies on slight elastic deformation of the gate for effective sealing. Temperature changes do not easily cause wedging, and the accuracy of the wedge angle is low. However, Care should be taken to prevent excessive closing torque and loss of elasticity in the ram, it is suitable for gate valves of various temperatures and pressures.

The wedge-type double gate has lower processing accuracy requirements for the wedge angle on the sealing surface. It is easy to seal and less prone to jams or scratches due to temperature changes. Maintenance becomes easier after the sealing surface is worn. However, this Design is more complicated with additional parts, leading to a larger and heavier valve.

The parallel single gate has a simple structure but cannot achieve self-forced sealing . In order to ensure its sealing performance, a fixed or floating soft seal is generally used.

Parallel double gates generally generate sealing force through the top wedge, within minimal relative movement between the sealing surfaces , reducing the risk of scratching. It is mostly used for low pressure, medium and small diameter gate valves.

Company name

Whatsapp number

*Phone No.

*Share your ideas

info@hankunchina.com

+86-15810403962

+86-15810403962

+86-15810403962

+86-(0)10-63260308