Post time: Jul-18-2023

Use Cases and Applications of Industrial Actuators in Various Industries

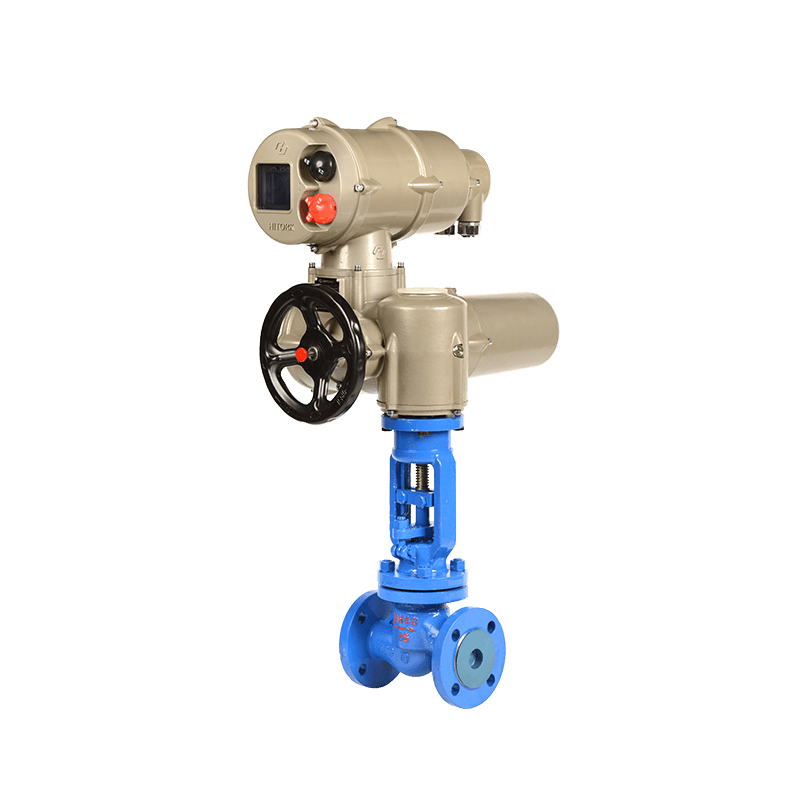

Industrial Actuators in the Oil and Gas Industry

Valve ActuationThe oil and gas industry extensively employs actuators to control the opening and closing of valves in pipelines, refineries, and drilling operations, ensuring seamless and safe operations.

Wellhead Control

Actuators are vital in controlling the wellhead equipment, regulating the flow of oil and gas during extraction operations, and ensuring proper well maintenance.

Pipeline Regulation

In long-distance pipelines, actuators are used for flow regulation and to maintain pressure within optimal ranges, optimizing the transportation of oil and gas.

Applications of Industrial Actuators in the Automotive Industry

Vehicle Braking SystemsIndustrial actuators play a crucial role in modern vehicle braking systems. Hydraulic actuators are commonly used in traditional braking systems, while newer electric actuators are making their way into electric and hybrid vehicles, providing regenerative braking and improved energy efficiency.

Throttle Control

In traditional internal combustion engine vehicles, throttle control regulates the flow of air and fuel to the engine, thus controlling the vehicle's speed. Electric actuators are increasingly used in throttle control, enhancing response times and fuel efficiency.

Suspension Systems

Modern automotive suspension systems incorporate actuators for active damping and height adjustment. These actuators enable vehicles to adapt to different road conditions, improving comfort and handling.

Engine Valves

Industrial actuators are employed in engine valve control, where precise timing and movement are vital for optimizing engine performance and fuel economy. Variable valve timing (VVT) systems rely on actuators to adjust valve timing as needed.

Industrial Actuators in Aerospace and Defense

Aircraft Control SurfacesIn the aerospace industry, precise control of aircraft surfaces is critical for stable flight. Hydraulic and electric actuators are extensively used in ailerons, elevators, and rudders to achieve precise control and maneuverability.

Missile Guidance Systems

Missiles and guided projectiles rely on sophisticated actuator systems for steering and trajectory adjustments during flight. These actuators ensure accuracy and agility in missile guidance systems.

Unmanned Aerial Vehicles (UAVs)

Industrial actuators are essential components in UAVs, providing control over various flight surfaces and payloads. The compact and lightweight nature of electric actuators makes them ideal for UAV applications.

Use of Industrial Actuators in Robotics and Automation

Industrial RobotsIndustrial actuators serve as the joints and limbs of industrial robots, enabling them to perform precise and repetitive tasks with efficiency and accuracy.

Collaborative Robots (Cobots)

Collaborative robots, designed to work alongside humans, utilize actuators that offer safety features and compliance to avoid potential workplace hazards.

Automated Assembly Lines

Actuators are widely used in automated assembly lines to handle, manipulate, and position various components during manufacturing processes, increasing productivity and reducing human error.

Applications in the Medical and Healthcare Sector

Medical DevicesIndustrial actuators find applications in various medical devices, such as infusion pumps, surgical robots, and prosthetic limbs, providing enhanced precision and mobility to aid patients.

Prosthetics and Orthotics

Actuators play a critical role in advanced prosthetic and orthotic devices, offering natural movements and improving the quality of life for individuals with limb impairments.

Industrial Actuators in the Marine Industry

Ship Steering SystemsIn the marine industry, hydraulic actuators are commonly used in ship steering systems, allowing for precise control and maneuvering of vessels.

Underwater Robotics

Industrial actuators are crucial in underwater robotic vehicles, helping researchers explore and study the ocean depths with ease.

The Role of Industrial Actuators in the Energy Sector

Power Plant ControlIndustrial actuators are utilized in power plants to control valves, dampers, and other critical components, optimizing energy production and distribution.

Renewable Energy Systems

Actuators are instrumental in various renewable energy systems, such as solar tracking systems and wind turbine pitch control, to maximize energy capture.

Actuators in Smart Buildings and Home Automation

HVAC SystemsActuators are integrated into heating, ventilation, and air conditioning (HVAC) systems, allowing for precise temperature and airflow control in smart buildings.

Automated Blinds and Curtains

In smart homes, electric actuators are used in automated blinds and curtains to adjust natural light and privacy settings based on user preferences.

Environmental Applications of Industrial Actuators

Air Quality ControlIndustrial actuators contribute to air quality control systems, such as air dampers in HVAC systems and pollution control equipment, enhancing indoor and outdoor air quality.

Actuators play a role in water management, controlling water flow in dams, irrigation systems, and wastewater treatment plants.

Advantages of Using Industrial Actuators

Industrial actuators offer several advantages that contribute to their widespread adoption:

Actuators provide precise and accurate motion control, ensuring consistent and reliable performance in various applications.

Many actuators are designed with energy efficiency in mind, reducing power consumption and operating costs.

Industrial actuators are built to withstand harsh conditions and heavy use, resulting in long-lasting and reliable performance.

The ability to remotely control and monitor actuators enables efficient operation and maintenance, especially in large-scale industrial settings.

Challenges and Limitations of Industrial Actuators

Despite their advantages, industrial actuators come with certain challenges and limitations:

Regular maintenance and occasional repairs are essential to ensure optimal performance and prevent downtime.

High-performance actuators can be expensive, especially for smaller businesses or projects with budget constraints.

Integrating new actuators with existing machinery or systems may require specialized expertise and careful planning.

Future Trends and Innovations in Industrial Actuators

As technology advances, industrial actuators continue to evolve, leading to exciting trends and innovations:

Advancements in miniaturization and nanotechnology are enabling the development of smaller and more efficient actuators suitable for micro-level applications.

Integration with artificial intelligence allows actuators to adapt and optimize their performance based on real-time data and environmental conditions.

The industry is moving towards developing eco-friendly and sustainable actuators, reducing environmental impact and energy consumption.

FAQs

1. Are industrial actuators only used in large-scale industries?No, industrial actuators find applications in both large-scale and small-scale industries. Their versatility and ability to provide precise motion control make them suitable for a wide range of applications.

2. How do hydraulic actuators differ from electric actuators?

Hydraulic actuators use fluid pressure for motion, while electric actuators rely on electric motors. Hydraulic actuators are known for their high force output, while electric actuators offer precise and efficient control.

3. Can industrial actuators be used in underwater environments?

Yes, industrial actuators designed for underwater use are commonly used in marine research and exploration, underwater robotics, and offshore operations.

4. Are industrial actuators capable of self-adjustment?

Some advanced industrial actuators integrate with sensors and artificial intelligence, enabling self-adjustment based on real-time data, enhancing their efficiency and adaptability.

5. What is the future of industrial actuators in the green technology sector?

The future of industrial actuators in the green technology sector looks promising. We are focusing on developing more sustainable and energy-efficient actuators to support eco-friendly initiatives.

For more information see "The Ultimate Guide to Electric/Pneumatic Actuators, Valve Actuators, and Industrial Actuators"